NON DESTRUCTIVE TESTING

The purpose of Non Destructive Testing is to detect defects in a test piece that may cause failure during service. To be non-destructive, the test must not be able to distinguish between test indications that could cause failure, and are therefore merely innocuous flaws or discontinuities. All NDT methods are capable of producing test indications that are spurious, that is to say the indications are not caused by a defect or flaw but are a result of the NDT process itself.

LONG RANGE ULTRASONIC TESTING

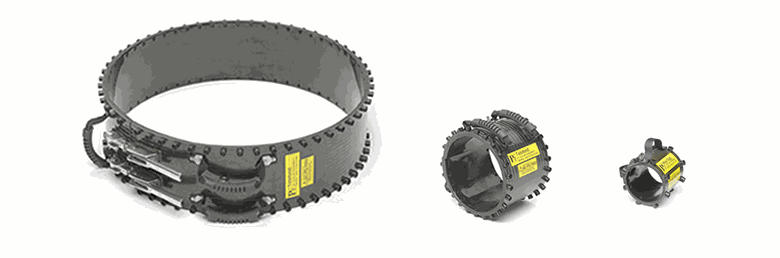

Long Range Ultrasonic Testing (LRUT) is one of the NDT method. It is a system facilitates a service for rapidly surveying pipes for corrosion and other degradation using ultrasonic guided waves. The operation consists of application of low frequency ultrasonic waves to the pipeline in order to detect material loss and other defects (internal and external) due to corrosion, erosion, mechanical damage or any other degradation process.

The waves are induced in the pipe wall by means of transducers that are excited after being attached to the outer surface of the pipeline. The tool assembly housing the transducers remains static in at the point of application whilst the condition of the pipeline is assessed by the soundwaves generated in the pipe wall and propagating along the pipe using the pipeline itself as a wave guide.

MALAYSIA

Main office

No.8 & 8A, Jalan 12/10,

Taman Koperasi Polis Fasa 1

68100, Batu Caves, Selangor

Malaysia.

Phone : +603-4108 1028 / 03-4101 9939

Email : info@pj-energy.com.my

THAILAND

PJ Energy Services Co., Ltd

No. 53/15 Soi Nimitmai 18, Nimitmai Rd., Saikongdin, Klongsamwa, Bangkok 10510, Thailand.

Phone : +662 906 9853-4 / +66 906 9855

Email : inquiry@pj-energy.com

.JPG)

%20(1).JPG)